The design for the Canton Tower in Guangdong, China, formerly known as the Guangzhou TV Tower, was won by Information Based Architecture (IBA) and Arup in 2004. Architects Mark Hemel and Barbara Kuit proposed one of the tallest buildings on the banks of the Pearl River in Guangzhou’s Tianhe District, standing at a height of 600m.

The architects aimed to design a free-form tower with a rich and human-like identity that represents Guangzhou as a vibrant and exciting city. The non-symmetrical form portraying the building ‘in movement’ has led to nicknaming it ‘the supermodel’.

The tower topped out in August 2009 and was completed in September 2010. It was officially renamed as Canton Tower, to represent the traditional European name of the city, and opened in October 2010.

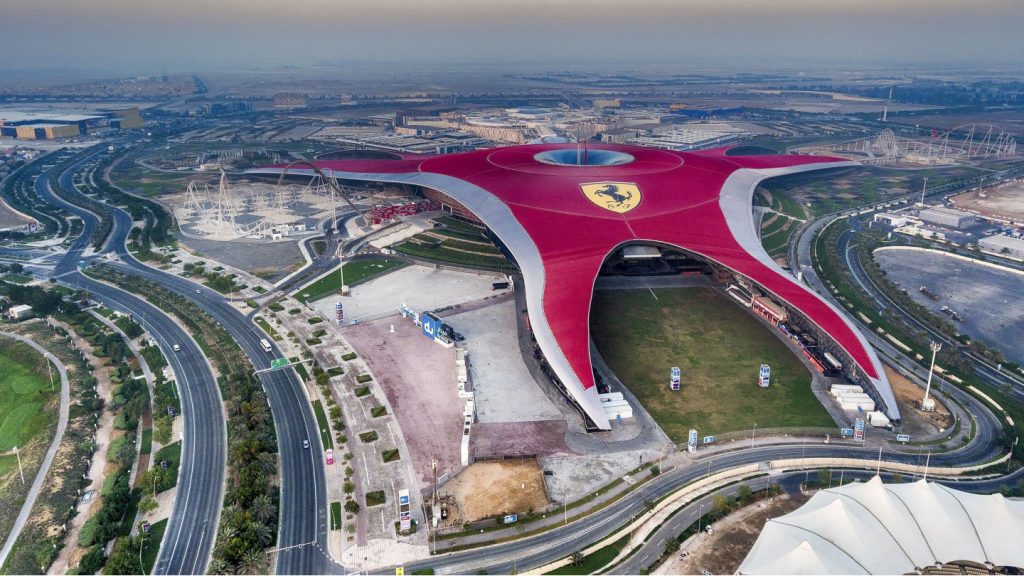

The access to the tower operates on two levels; one as a continuity of the landscape on ground, and another linked to the mass-transit and underground-parking facilities.

The base of the tower encompasses a museum, food court, extensive commercial space and a 600-vehicle parking area. It also stores the infrastructural connections (metro and bus stations) and a pedestrian link to the northern embankment of the river.

The core of the television tower consists of a concrete elliptical shaft with a short and long diameter of 15.6m and 18.6m respectively.

The more-open structure at the top generates a transparent condition ideal for observation activities, while the denser areas in the waist of the building provide a more intimate experience.

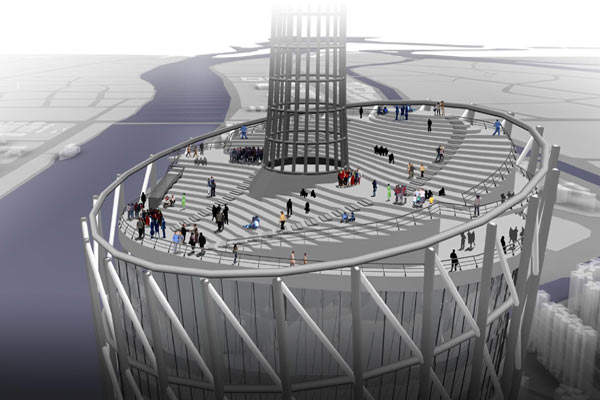

The waist of the tower has a 180m-long open-air skywalk for visitors to stroll around and get the feel of the tower’s structure and waist line. Above the staircase, which begins at 170m and spirals to 200m high, begins the top zone housing technical functions, a two-storey rotating restaurant, a damper and the upper observation levels.

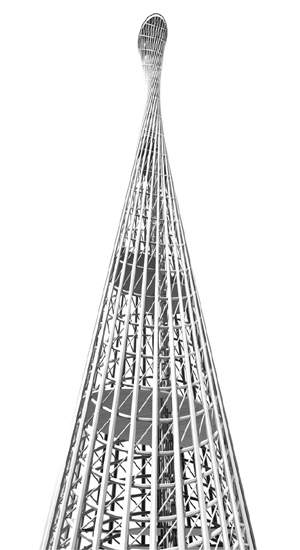

Structure of Canton Tower

A further set of stairs leads to a terraced observation square which rises above the tower’s top ring. From the top deck at the level of 454m, the antenna extends another 146m.

In total, the building has 48 steel floors with 37 functional floors divided into five ‘climate zones’, such as tropical, desert, temperate, providing 114,054m² of multipurpose recreational areas. Each floor has been designed differently with regard to size, exposure, users and events. The mixed-use building includes gardens, a hotel, a museum, cinema theatre, showrooms and a restaurant.

The hyperboloid structure is in the form of a twisted and tapering tube. The outer steel-framed structure consists of 24 steel columns with concrete in-fill, a series of 46 oval-shaped rings of different sizes and single-direction diagonals throughout the structure.More than 40,000t of structural steel (including the mast) has been used for the project.

The form is generated by two ellipses, one at the foundation level and the other at an imaginary horizontal plane just above 450m high. The tightening caused by the rotation between the two ellipses is the reason for the tight ‘waist’, and is in the form of a twisted rope.

Waist structure of Guangdong’s Canton Tower

One of the main issues that had to be kept in mind regarding the cost was the client’s desire to have the tightest ‘waist’ possible. According to the architect Mark Hemel, the waist of the tower structure was a complex issue as it depends on several other elements, such as the six public elevators, determining the space required for the core.

The waist structure was complex as any change in its size would result in changes to the structural steel density to mitigate the wind pressure.

As such, the circular core was optimised to an oval in order to fit it within the tightest waist possible.

The waist consists of a band between 270m and 300m high, measuring 20.65m by 27.5m from centre to centre column.

Hence, taking into account a structural zone of about 3.5m; there was only about 15.6m space across for the core to fit into, excluding tolerances required for movement of the tower. This core is for the lifts, escape stairwell and vertical building services risers.

Columns, rings and diagonals form together a web that varies over the section of the tower. The columns are all perfectly straight although they lean over to one direction, giving the tower a dynamic twist. The rings are placed on the far inside of the columns so they spatially miss each other and are connected off-centre.

This makes the inside view to be dominated by the rings, while the view from the outside is dominated by the sloping columns. All rings have been placed under an angle of 15°, so that an opening is created both for the entrance at the base of the tower, as well as that a sloping deck at the top of the building, offering magnificent views over the city.

At the bottom of the tower the columns are 2m in diameter, constructed of 50mm thick plated steel that is bent fully round in 3.7m wide bands that are welded together. At the top of the tower the column diameter is reduced to 1,100mm with a plate thickness of 30mm.

Complex geometry of Canton Tower

The complex geometry was possible due to parametric associative software, which is capable of generating geometrical and structural models based on a set of variable parameters and link the geometrical data to the analytical and drafting software. The firm has adopted the most advanced technologies in wind engineering and wind tunnel studies based on sectional models with computer stimulation. Using the wind data, a series of performance-based design options were assessed.