Rockwool International has patented a method for bonding surfaces of elements, including mineral wool, using an adhesive that contains proteins and phenolic compounds. The process involves applying the adhesive to surfaces before or during contact and curing it to achieve a strong bond. GlobalData’s report on Rockwool International gives a 360-degree view of the company including its patenting strategy. Buy the report here.

According to GlobalData’s company profile on Rockwool International, Structure Building Framework was a key innovation area identified from patents. Rockwool International's grant share as of July 2024 was 55%. Grant share is based on the ratio of number of grants to total number of patents.

Method for bonding mineral wool elements using specific adhesive

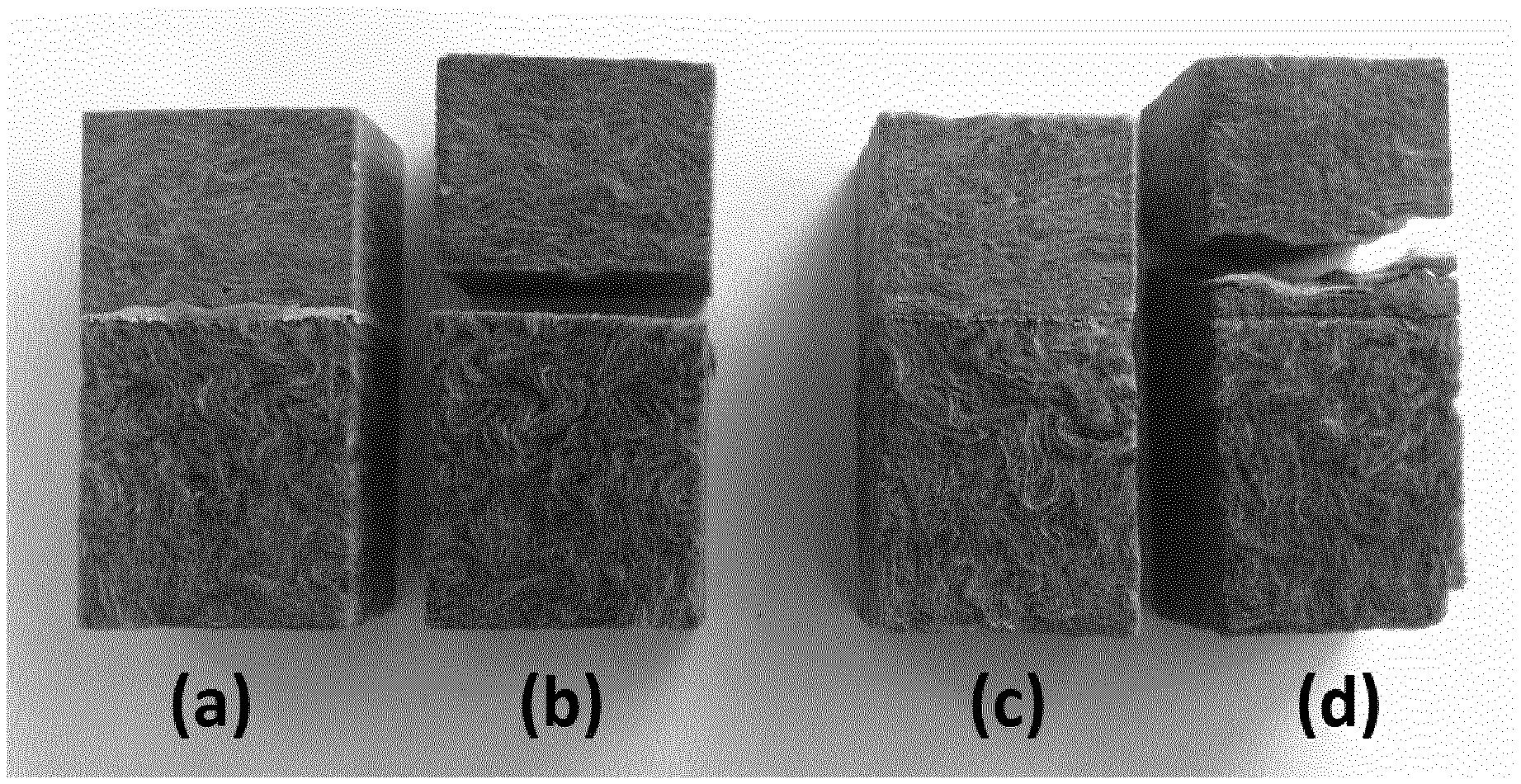

The patent US12070929B2 outlines a method for bonding surfaces of two or more elements, specifically incorporating at least one mineral wool element made from man-made vitreous fibers. The bonding process involves applying an adhesive to the surfaces intended for bonding, followed by the contact and curing of these surfaces. The adhesive is characterized by containing at least one protein, which includes lysine and/or cysteine, and at least one phenol or quinone compound. The specified mass ratio of the protein components to the phenolic components ranges from 1:5.78 to 1:0.08. The method allows for the bonding of multiple mineral wool elements or a combination of mineral wool and non-mineral wool elements, with curing temperatures ranging from 5°C to 95°C.

Further claims detail the composition of the adhesive, which may include various proteins derived from sources such as collagen, gelatin, and plant-based proteins, as well as a wide range of phenolic and quinone compounds, including synthetic variants. The adhesive may also contain additives like oxidants, metal ions, and pH adjusters, with a pH value maintained between 7 and 10. The mineral wool elements can be in various forms, such as fabrics, mats, or slabs, and are suitable for applications in thermal and acoustical insulation, vibration damping, and construction materials. Notably, the mineral wool binder used in these elements is specified to be a non-phenol-formaldehyde binder, indicating a focus on alternative bonding agents in the manufacturing process.

To know more about GlobalData’s detailed insights on Rockwool International, buy the report here.

Data Insights

From

The gold standard of business intelligence.

Blending expert knowledge with cutting-edge technology, GlobalData’s unrivalled proprietary data will enable you to decode what’s happening in your market. You can make better informed decisions and gain a future-proof advantage over your competitors.