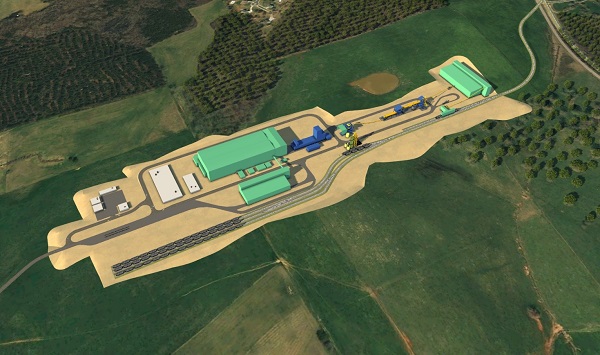

Piedmont Lithium has announced its plans to build 30,000 metric tonne per year LHP2 lithium hydroxide plant at Etowah, in McMinn County, Tennessee, US.

The $600m project is expected to complete and start production in 2025.

Discover B2B Marketing That Performs

Combine business intelligence and editorial excellence to reach engaged professionals across 36 leading media platforms.

Piedmont claims that the Tennessee lithium project will become the largest lithium hydroxide processing facility in the US.

The facility will transform spodumene concentrate sourced mainly from Piedmont’s international project investments.

This investment will expand the supply of lithium hydroxide, which is a main component in the production of EV batteries, in the country.

The project will create almost 120 jobs.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataPiedmont’s Tennessee Lithium facility will be one of the first lithium hydroxide plants constructed with the Metso: Outotec process, which removes the acid-leakage of spodumene and sodium sulfate waste production.

This facility will complement the company’s planned Carolina Lithium facility.

Together, these projects will take the firm’s total production capacity in the country to 60,000 tonnes per year by 2026.

Currently, the total US production of lithium hydroxide stands at 15,000 tonnes per year.

Piedmont Lithium president and CEO Keith Phillips said: “The rapid electrification of the automotive market has led to massive investments in electric vehicle and lithium-ion battery production in the United States, creating a critical need for lithium hydroxide produced in the US.”

The company chose Tennessee to build the facility due to its access to infrastructure, including rail, road and river transportation, as well as its proximity to the battery and automotive plants being built.

Kiewit and Primero will execute front-end engineering design (FEED) for Tennessee Lithium project.

—————————————————————————————————————–

Image: Conceptual design of the 30,000 tonnes per year Tennessee Lithium plant. Credit: Business Wire /Piedmont Lithium.